FOAM

After much research, we realized that polyurethane (PU) or polystyrene (EPS) foam poses risks not only to the environment after disposal, but also to the health of shapers. That was it! This was the first material in the “perfect surfboard” equation that we decided to address.

We found a biodegradable polyurethane foam based on vegetable oil used in the areas of civil engineering, agronomy and medicine with very interesting characteristics for what we were looking for.

While PU or EPS foam takes about 400 years to decompose in nature, this foam decomposes in up to 9 months. Amazing, right? But don’t mistake this rapid decomposition for something that doesn’t last long; this process only happens in favorable environments, such as landfills and dumps (which coincidentally is the most common destination for surfboards).

Despite its many positive points, its replacement was not easy. Right away, we detected characteristics in this foam that set it apart from the polyurethane used in surfboards. Its density, color, homogeneity, weight, spacing between cells… some things needed to change. That’s how our work began.

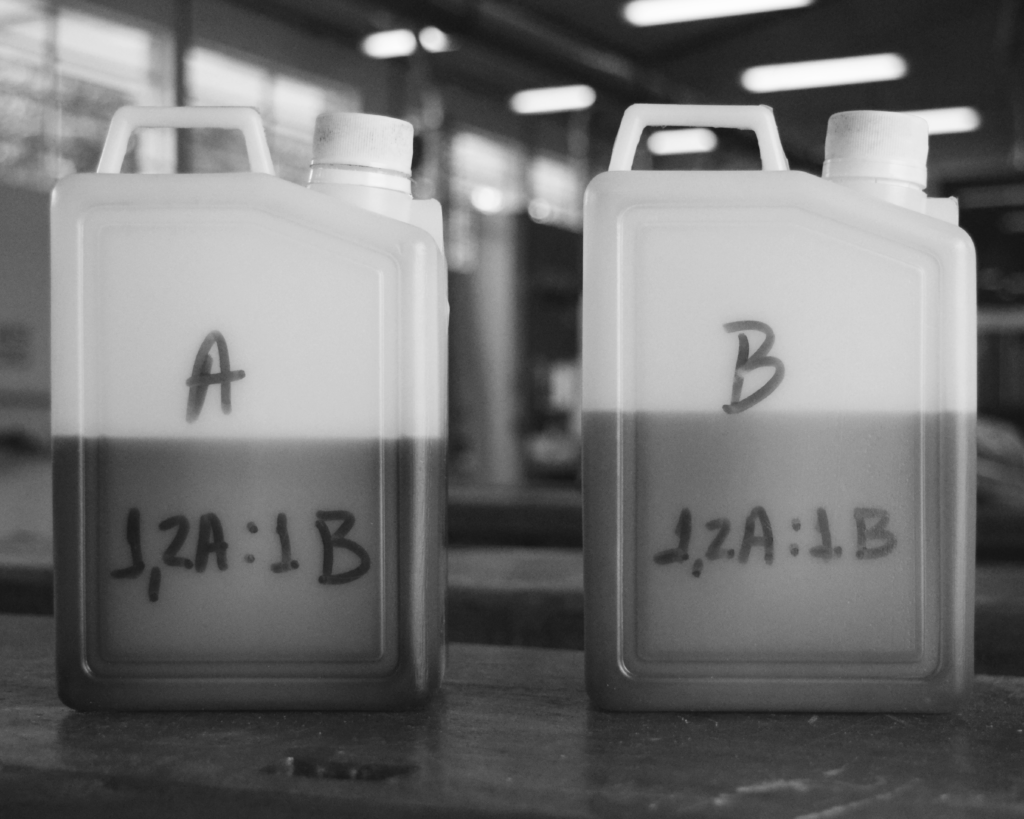

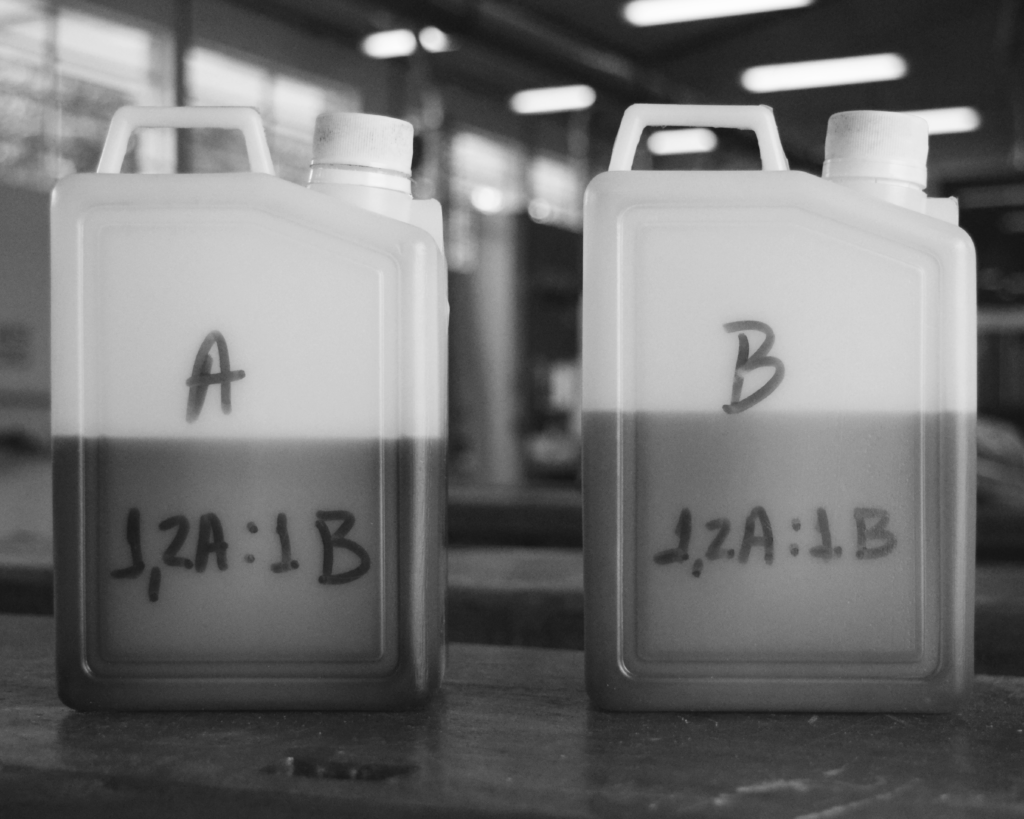

After years of testing involving chemists, shapers, surfers, designers, partners, family, friends and many supporters, José Octávio and Esther arrived at a very promising and exciting formulation. What are the next steps?

Find out in the tab SURF IN SYNC.